How to maintain your brakes

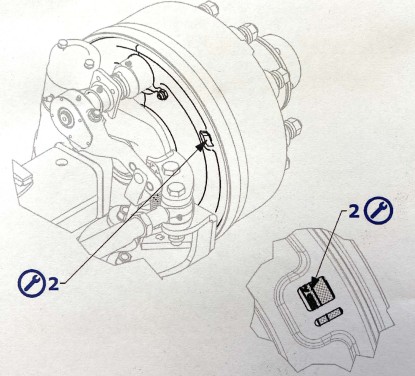

2) Every 500 working hours (or every 8500km travelled).

Check brake friction gasket wear. Open both inspection windows on the back of the brake and check friction material thickness outside the reference line.

The reference line should always be well visible and, for machine safety, it is best to replace the brake friction gaskets when material thickness outside the line is reduced to 2mm. Always use original friction gaskets of the same type as those to be replaced.

Friction gasket features are indicated next to the gasket inside the reference line.

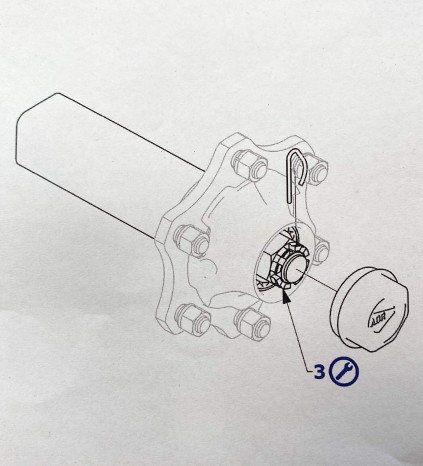

3) Bearing gap check (version with press-in hub cap)

After the first 200 working hours at full load (or after the first 300km travelled), afterwards every 1500 hours (or every 2500km travelled).

Make sure the wheel bearing do not rock. This check is performed by lifting the axle with a jack until the wheel is off the ground and rotates freely. Insert a lever between the ground and tyre and force the wheel up to find any gaps.

Bearing gap adjustment:

- Remove the hub cap.

- Remove the elastic stop pin on the rack nut.

- Tighten the rack nut while simultaneously rotating the wheel until the hub is slightly braked.

- Rotate the rack nut until a slot with the hole on the spindle is found and insert the elastic pin. Make sure the hub rotates manually with slight resistance - top up ADR Lithogrease (3). Grease on the visible part of the bearing and reassemble the hubcap.