9 Tonne Combo

Versatility plus.

Like all SAM Spreaders, SAM Combos are very easy to operate and maintain. They are also more flexible around what the operator is able to spread.

They are able to spread the usual granulated and powder fertilisers such as urea, super and lime. They also work well with the majority of organic fertiliser materials for example; chicken manure, pig manure, screw pressed products and sand.

Sizes come in 3.8, 6 & 9 tonne. All have a belt on the floor that is 800mm wide. The 9 tonnes are tandem axle only.

Keep it simple with a standard hydraulic clutch to ground drive, add load cells, or upgrade to the latest smart, accurate Topcon control system

4.99% FINANCE

For new SAM spreaders sold and delivered by 31st of March, 2024, you can get 4.99% p.a.~ finance* over 36 months with a 10% deposit and the GST repaid back on the 4th month.

*Offer of finance at 4.99% interest per annum on new SAM products is available only to approved ABN holders on new equipment sold and delivered by 31st March 2024. Commercial credit and lending criteria apply to PFG Credit applications. Offer available to approved PFG Credit applications. Offer requires a minimum of 10% deposit/equity at settlement followed by 36 equal monthly repayments and the GST equivalent repaid back in the 4th month. PFG Credit is a division of De Lage Landen Pty Limited ABN 20 101 692 040.

Smart features

-

More stainless for longevity

Majority stainless at the rear of the machine, extends longevity of gear where you need it most. The stainless discs are run via enclosed stainless spinner tubes and two well-proven hydraulic motors. Easily adjustable tapered roller bearings keep disks tight.

-

Corrosion resistant paintwork

All chassis's on SAM Spreaders have seen a new evolution of painting procedure. This is for extra corrosion protection. Firstly a steel grit abrasive blast then a thermal-arc pure zinc spray, a primer followed by a final two-pot epoxy top-coat. It is mega tough stuff!

-

Strong plastic bin

The polyethelyne plastic bin has proven to be extremely reliable. They are strong, corrosion resistant and UV-stabilised. Fertiliser also slips down the sides and washes off easily when you are cleaning your gear.

-

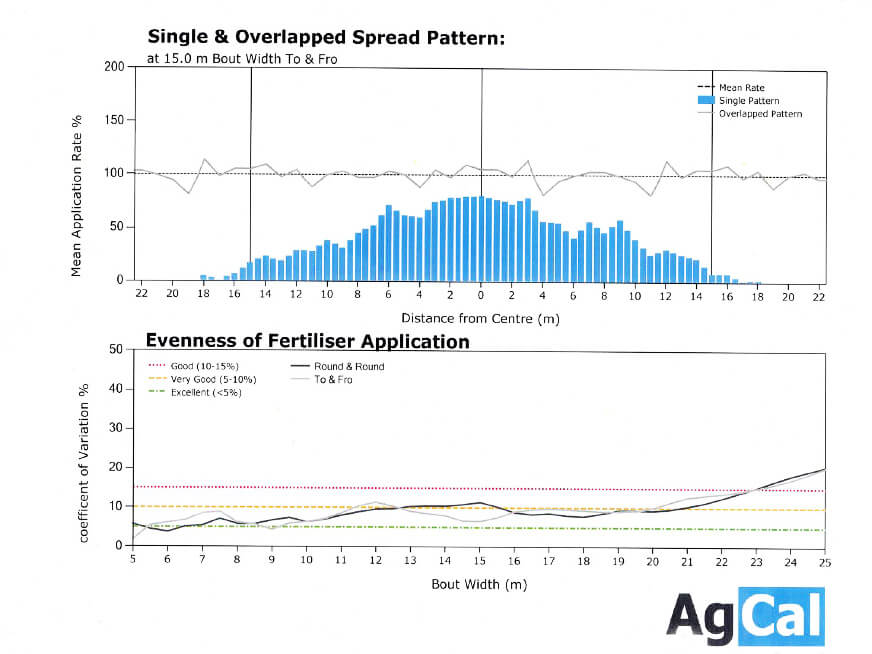

Even, accurate spread

The SAM twin spinner disc design gives an accurate and consistent spread pattern across a range of products. Quick and simple rate setting is by adjusting the rear door.

-

Load weigh scales

You can add scales to your spreader. This gives simple, accurate electronic weighing of your feed. And can be zeroed out any time. More info below.

-

Topcon control system

You can also add a Topcon control system to replace the standard ground drive. This gives hydraulic floor speed rate and control. This technology means the correct application rate is applied regardless of changes in forward speed or changes in product density. Gives peace of mind for accuracy and reporting.

-

Rubber floor-belt (800mm wide)

Provides a positive non-slip feed of fertiliser onto the spinner discs. A patterned two-ply rubber floor-belt is riveted to hot-dip galvanised steel bars, welded to high-tensile chain. Stainless skirts run alongside.

-

Material agitator

This optional extra is designed to break up and crumble organic material like screw pressed effluent. This improves the flow to fall consistently onto the spinner discs.

-

Easy greasing

Remote greasing is included on all 8 & 9 tonne models. All grease points are raised together so they are easy to reach, saving you time and effort with your maintenance.

-

Protective mesh

Stops large objects dropping down and damaging the belt and gear.

-

App for verifying rates

A great check against your back door setting to verify exactly what you are spreading. This is for use with Spreaders fitted with load cells. Currently Android only.

-

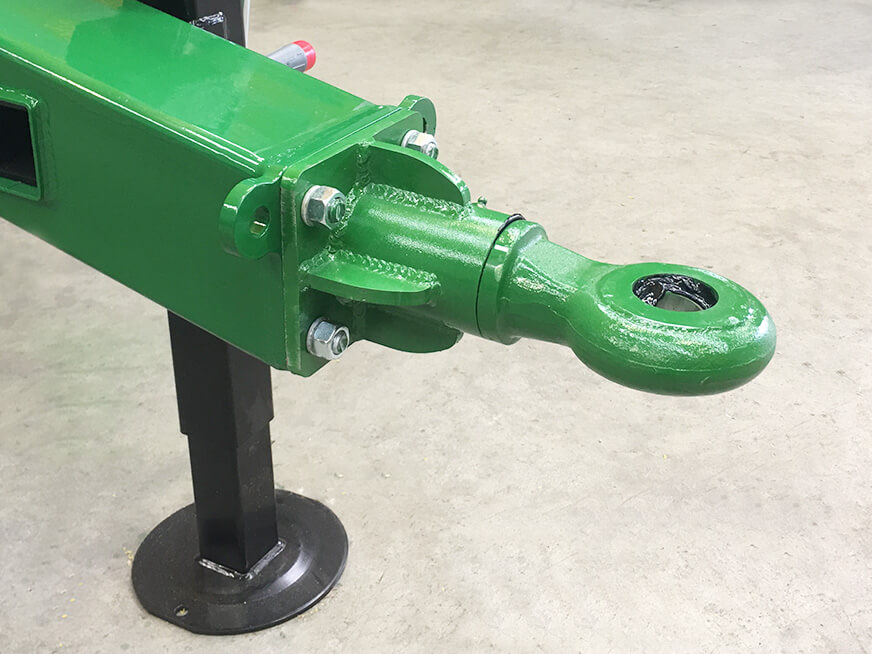

Swivel coupling adds stability

Smaller spreaders come standard with a fixed coupling. The 6, 8 and 9 tonne spreaders come standard with a heavy-duty swivel coupling. They are great for varied terrain. You can choose a donut eye for coupling with a quick hitch or the ball option for tractor coupling.

-

Roll top cover

These simple to use roll out covers have a heavy-duty canvas on a sturdy framework with a simple bungy system. The cover is rolled up by the handle and tucked out of the way when you are not using it. The roll-top is located at the rear of the machine so that your Spreader is able to be loaded from both sides.

Optional extras

- New smart computer drive

- Scales for weight measurement

- Brakes on front hubs

- Lights for on-road use

- Agitator - breaks up material for better flow

- Mudguards for added protection

- Larger tyres

- Stainless steel hydraulic hose fittings

New smart computer drive

If even more accuracy and control is needed, go for a computer controlled system. This is instead of the normal ground drive.

This technology means the correct application rate is applied from the cab, regardless of changes in forward speed or changes in product density.

You can go for rate control only, or add weigh scales for extra precision and automatic rate calibration.

A GPS aerial is great for proof of placement and field mapping. Find out more.

Scales for weight measurement

Manual drive spreaders

Load cells give an accurate measure of the weight of product in the bin. They can be zeroed at any time.

A simple calculation of the weight of product spread, divided by the area covered, gives you the spread rate (in kg/ha). Many new tractors have an inbuilt display that will give area covered at certain spread widths.

A fixed Iconix FX15 display unit is supplied with all manual SAM machines fitted with weigh scales. It is mounted to the front of your spreader.

A simple App for Bluetooth viewing on your mobile is also available (currently Android only). This App allows you to verify your spread rate at any point in time.

Computer drive (Topcon)

You can also add load cells to any computer controlled machine. Most are spec'd this way. It is really the only way to get true accuracy because you are actually weighing the product in the bin.

Brakes on front hubs

All tandem axle SAM's can have brakes fitted. They are positioned on the two front hubs.

Brakes are chosen for their longevity and have proven to be extremely reliable across the years.

Lights for on-road use

You will need LED lights and flags if you are travelling on the road. The flexible plastic mounting boards are tough and hardy if knocked.

The LED lights plug straight into your power source. They are fully waterproof.

Agitator - breaks up material for better flow

The agitator has been created to break and crumble heavier bulkier material like screw pressed effluent. This enhances the flow of product onto discs.

Mudguards for added protection

Standard on all tandem axle machines (except 8 & 9 tonne) SAM mudguards are made from UV-protected, high strength polyethylene. Cleaning and chips to chassis are reduced and they hold up well to abrasive chemical fertilisers.

For 8 & 9 tonne machines mudguards are available as an extra.

Larger tyres

Our tyres have been chosen for their toughness and durability. We only go for very high quality options for you.

Four and five tonne SAM Spreaders come standard with 11.5x15.3 tyres. Or you can upgrade to bigger 400x15.5 tyres. Bigger tyres can be suitable for softer, wet terrain.

Six tonne Spreaders have these 400x15.5 tyres included as standard or can be upgraded to 500/50x17 tyres.

For every single-axle model 550 / 60x22.5 tyres are an upgrade option.

Tyre specifications can be adapted for your particular situation. We are happy to talk through custom options.

Stainless steel hydraulic hose fittings

Higher grade hydraulic hose fittings for rust protection.

Specifications

- Axle 80 millimetres (tandem-axle)

- Axle capacity 16,000 kilograms

- Tyres 500/60x22.5

- Jack 70mm screw jack (tandem-axle)

- Overall (length) 6.1 metres

- Overall (width) 2.75 metres

- Overall (height) 2.38 metres

- Bin (width) 2.1 metres

- Bin (length) 4.1 metres

- Capacity 7.6 cubic metres

- Superphosphate 9 tonnes

- Lime 11 tonnes

- Urea 3.2 tonnes

Need help fast?

Contact your local dealer or call SAM for technical help and support.

Quality guaranteed

SAM makes quality machines and stands by them. Every Spreader goes through extensive quality and accuracy testing. All come with a comprehensive warranty.